June 12: Turkish Rugs

The Swissotel lets us breakfast early because we have a long travel ahead of us. (Did I mention the great buffet the Swissotel has? Much like the Divan. We could select from an incredible variety of foods.) On the way, we pass through Selcuk again. I like these photos of the fort above the town and of the storks' nest.

We settle into our long bus ride to Gocek and the gulets. Then, an unexpected treat. We know the plan is to stop and see a demonstration of carpet weaving, but we didn't expect it to be more than a diversion. We were wrong!

Thirty minutes into the trip we stop at the small village of Camlik. As I have written ad nauseum, our days so far have been spent spent walking through fascinating but crowded ruins. Under blaring suns.

Today, we enter an oasis of quiet walkways, green lawns, and huge trees. This is Camlik, and a carpet weaving facility. But more than that.

As we walk closer to the small white buildings, we see two women sitting at weaving looms:

We soon find that we are not here to see just a demonstration of carpet weaving, we are also here to learn of Sultamkoy, an organization that works with villages to benefit local women and the rug company as well as keep the ancient tradition of rug weaving alive.

Here's how it works. Sultamkoy employs young women aged 15 and above from local farming villages. They school these women in the art of rug weaving and pay them as they learn. Buses pick them up from their villages in the morning, and return them each late afternoon. The women have their meals at the school, and can even bring young children. The company profits from the sale of the rugs. The traditional art of Turkish rug weaving is passed on to a new generation. It's a win-win situation, and an intelligent and community-oriented way of running a business. I was impressed.

Our guide through the facility was an entertaining, ethusiastic guy. You can hear him talking in this movie of a demonstration of the double-know weaving technique.

Isn't that totally cool?

I took some still photos too.

Yarns for the weavings are dyed right at the factory. Most of the dyes they use are extracted from local plant sources. Here are the vats for the dyes:

Plant materials used for the dyes are in the barrels under the hanging dyed yarns:

I got all excited about the dyeing process. This is what I used to have organic chemistry students do in lab! We taught them about the chemistry of dyeing. Briefly, dyes adhere to fabrics by different chemical means. Some adhere by ionic bonds, some by covalent bonds, and some simply get trapped in the fibers of the fabric. Different fabrics work differently with different dyes. (That's the short version. If you want the long version, read the essay I wrote on Dyes and Dyeing for the organic chemistry lab students at the University of Colorado, Boulder, in the 1990s.)

The history of civilization includes the development of ways to color cloth. Early dyes were isolated from plant sources, and as civilization grew, the seeds for these plants and the dyeing methods were closely guarded. Beautifully dyed clothing was worn by the rich, dyed cloth was taken along ancient trade routes. Later, in the nineteenth and twentieth centuries, the demand for synthetic dyes helped initiate the science of organic chemistry, leading eventually to the chemical industries that we still have today.

I've always found indigo especially interesting. Partly because I switched from dresses to indigo-dyed blue jeans when I was about 19 and a semi-hippie, and partly for indigo's unique chemistry. When indigo is in its reduced form, it is soluble in water and a light yellow. If you put fabric in a solution of this reduced form of indigo, then pull it out into the air, the indigo oxidizes and forms a solid, intense blue color. This dye is only "caught" in the fabric strands, so your blue jeans fade with time.

I'm pretty geeky but I sure got excited when they demonstrated the dyeing of yarns with indigo. I took a movie:

On the shelf in the photo below are some solid dyes. The blue one sure looks like indigo to me, and the white powder is likely a type of mordant. One type of mordant is a heavy metal salt that complexes with an organic compound to form a colored compound: a dye. Tannic acid, isolated from the bark of plants, is also a mordant.

Some of the yarn used in this company's rugs is wool, some silk. I believe the wool is from local animals, and I know the silk is produced here in Turkey.

The story of silk is interwoven with the history of civilization. Our host guide talked at some length about how the silk worms and the mulberry trees that they live on came to be cultivated in Turkey. The process is this: silk moths lay the eggs, the eggs hatch and develop into caterpillars called silk worms, the silk worms are fed mulberry leaves, eventually they spin a cocoon of a strand of silk that is a mile long, finally, most of the cocoons are heated to destroy the insects (some are allowed to mature to for the next generation of silk worms). Three to ten strands of silk are then joined to form a single thread of silk.

Here are a couple shots of silk cocoons, floating in a pool of water:

Each white, ovoid ball is a single strand of silk wound around the caterpillar stage of a silk worm. He let us hold and shake a cocoon - we could hear the dead bug rattle around inside.

But how is this ball of silk unwound and made into threads? The next two movies show these processes.

It's so amazing how the guy untangled the silk threads.

Now it's time to see the rugs: the final products of the preparation of yarns and the weaving by the women. We go into a big room full of rugs and are served beverages as we sit on benches against the walls.

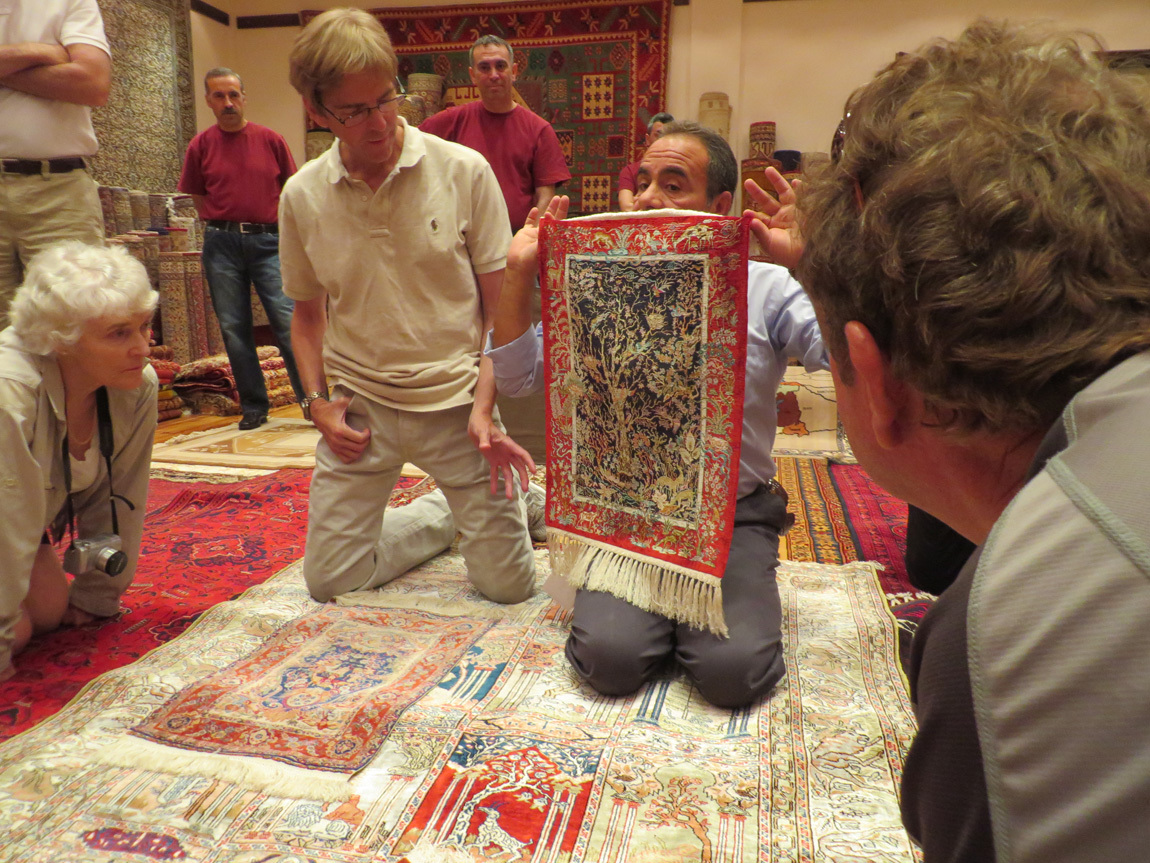

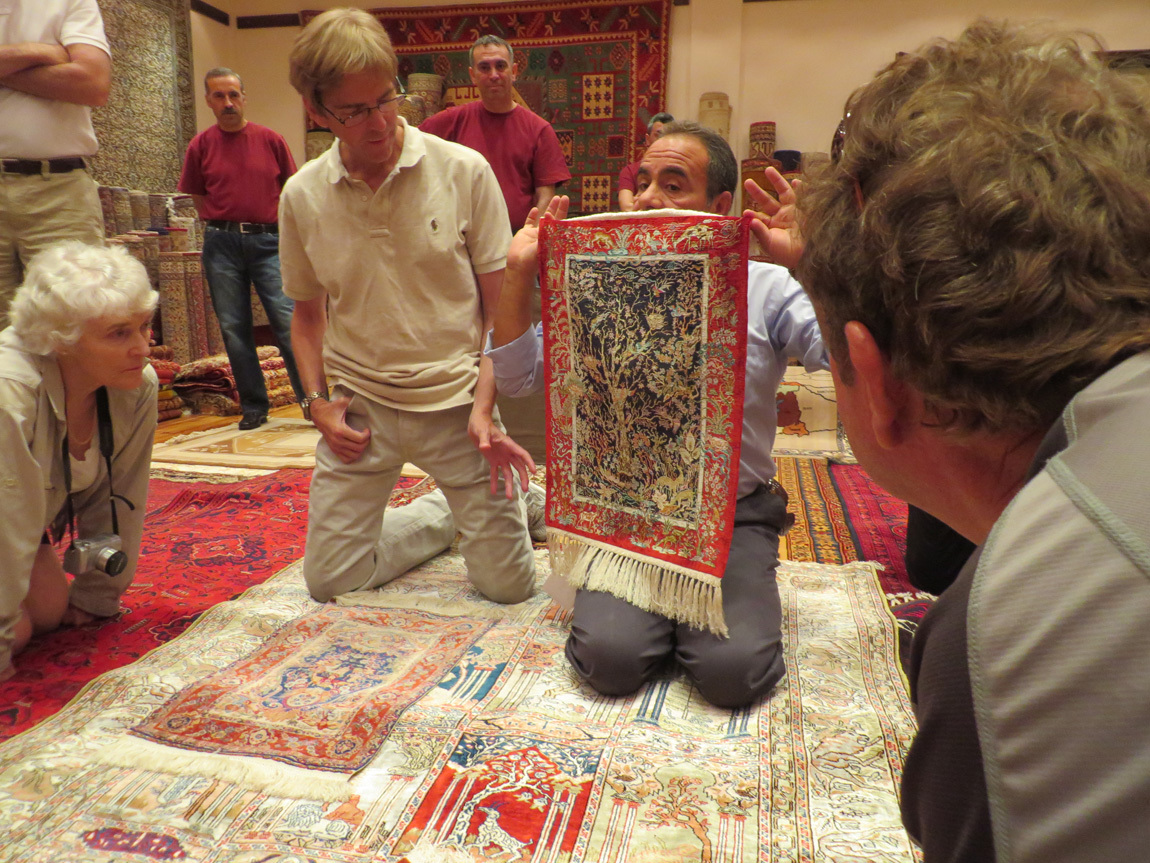

Our host shows us tons of rugs and talks about what to look for in a authentic, good quality Turkish rug. Pretty much, the more knots per inch the more detail - the more pixels as an analogy to today's computer graphics - the design will have and the more expensive they will be (because they take longer to make). You can look for the number of threads in the fringe. Also, the design has to be seen on the back as well as the front. There's more to it than that; I understood it at the time but I'm afraid it went in one ear and out the next, as we have no desire to own one. Doesn't quite fit into our rustic lifestyle. But I could sure appreciate the beauty of their rugs. They were pricey, but several members of our tour group purchased some.

Showing the back of rugs:

We are allowed to walk on the rugs, get down and touch them:

This large rug looks different from different directions:

Here is our host and the multitude of rugs that they have rolled out.

The rugs take from 3 months to a year and a half to weave, probably even longer for the ultra-high quality ones. The best weavers get a reputation, and their rugs are collected as fine art. Like these:

Look at the detail:

We wander around the grounds as some tour members purchase rugs. Ali sits in the courtyard and plays the baglama. I got a kick out of the his/hers signs for the water closets:

Tables are set with white linens on the lawn.

We sat at those tables under the trees and had yet another great meal. The food was all locally produced and fresh as could be. We enjoyed our wine and watched the view and roosters and a Turkish squirrel.

Meal:

View:

Turkish squirrel:

Rooster:

After four hours at this unexpected gem of a stop, we got back on the bus for the drive to our gulets.

Navigation:

first Turkey post

next Turkey post

We settle into our long bus ride to Gocek and the gulets. Then, an unexpected treat. We know the plan is to stop and see a demonstration of carpet weaving, but we didn't expect it to be more than a diversion. We were wrong!

Thirty minutes into the trip we stop at the small village of Camlik. As I have written ad nauseum, our days so far have been spent spent walking through fascinating but crowded ruins. Under blaring suns.

Today, we enter an oasis of quiet walkways, green lawns, and huge trees. This is Camlik, and a carpet weaving facility. But more than that.

As we walk closer to the small white buildings, we see two women sitting at weaving looms:

We soon find that we are not here to see just a demonstration of carpet weaving, we are also here to learn of Sultamkoy, an organization that works with villages to benefit local women and the rug company as well as keep the ancient tradition of rug weaving alive.

Here's how it works. Sultamkoy employs young women aged 15 and above from local farming villages. They school these women in the art of rug weaving and pay them as they learn. Buses pick them up from their villages in the morning, and return them each late afternoon. The women have their meals at the school, and can even bring young children. The company profits from the sale of the rugs. The traditional art of Turkish rug weaving is passed on to a new generation. It's a win-win situation, and an intelligent and community-oriented way of running a business. I was impressed.

Our guide through the facility was an entertaining, ethusiastic guy. You can hear him talking in this movie of a demonstration of the double-know weaving technique.

Isn't that totally cool?

I took some still photos too.

Yarns for the weavings are dyed right at the factory. Most of the dyes they use are extracted from local plant sources. Here are the vats for the dyes:

Plant materials used for the dyes are in the barrels under the hanging dyed yarns:

I got all excited about the dyeing process. This is what I used to have organic chemistry students do in lab! We taught them about the chemistry of dyeing. Briefly, dyes adhere to fabrics by different chemical means. Some adhere by ionic bonds, some by covalent bonds, and some simply get trapped in the fibers of the fabric. Different fabrics work differently with different dyes. (That's the short version. If you want the long version, read the essay I wrote on Dyes and Dyeing for the organic chemistry lab students at the University of Colorado, Boulder, in the 1990s.)

The history of civilization includes the development of ways to color cloth. Early dyes were isolated from plant sources, and as civilization grew, the seeds for these plants and the dyeing methods were closely guarded. Beautifully dyed clothing was worn by the rich, dyed cloth was taken along ancient trade routes. Later, in the nineteenth and twentieth centuries, the demand for synthetic dyes helped initiate the science of organic chemistry, leading eventually to the chemical industries that we still have today.

I've always found indigo especially interesting. Partly because I switched from dresses to indigo-dyed blue jeans when I was about 19 and a semi-hippie, and partly for indigo's unique chemistry. When indigo is in its reduced form, it is soluble in water and a light yellow. If you put fabric in a solution of this reduced form of indigo, then pull it out into the air, the indigo oxidizes and forms a solid, intense blue color. This dye is only "caught" in the fabric strands, so your blue jeans fade with time.

I'm pretty geeky but I sure got excited when they demonstrated the dyeing of yarns with indigo. I took a movie:

On the shelf in the photo below are some solid dyes. The blue one sure looks like indigo to me, and the white powder is likely a type of mordant. One type of mordant is a heavy metal salt that complexes with an organic compound to form a colored compound: a dye. Tannic acid, isolated from the bark of plants, is also a mordant.

Some of the yarn used in this company's rugs is wool, some silk. I believe the wool is from local animals, and I know the silk is produced here in Turkey.

The story of silk is interwoven with the history of civilization. Our host guide talked at some length about how the silk worms and the mulberry trees that they live on came to be cultivated in Turkey. The process is this: silk moths lay the eggs, the eggs hatch and develop into caterpillars called silk worms, the silk worms are fed mulberry leaves, eventually they spin a cocoon of a strand of silk that is a mile long, finally, most of the cocoons are heated to destroy the insects (some are allowed to mature to for the next generation of silk worms). Three to ten strands of silk are then joined to form a single thread of silk.

Here are a couple shots of silk cocoons, floating in a pool of water:

Each white, ovoid ball is a single strand of silk wound around the caterpillar stage of a silk worm. He let us hold and shake a cocoon - we could hear the dead bug rattle around inside.

But how is this ball of silk unwound and made into threads? The next two movies show these processes.

It's so amazing how the guy untangled the silk threads.

Now it's time to see the rugs: the final products of the preparation of yarns and the weaving by the women. We go into a big room full of rugs and are served beverages as we sit on benches against the walls.

Our host shows us tons of rugs and talks about what to look for in a authentic, good quality Turkish rug. Pretty much, the more knots per inch the more detail - the more pixels as an analogy to today's computer graphics - the design will have and the more expensive they will be (because they take longer to make). You can look for the number of threads in the fringe. Also, the design has to be seen on the back as well as the front. There's more to it than that; I understood it at the time but I'm afraid it went in one ear and out the next, as we have no desire to own one. Doesn't quite fit into our rustic lifestyle. But I could sure appreciate the beauty of their rugs. They were pricey, but several members of our tour group purchased some.

Showing the back of rugs:

We are allowed to walk on the rugs, get down and touch them:

This large rug looks different from different directions:

Here is our host and the multitude of rugs that they have rolled out.

The rugs take from 3 months to a year and a half to weave, probably even longer for the ultra-high quality ones. The best weavers get a reputation, and their rugs are collected as fine art. Like these:

Look at the detail:

We wander around the grounds as some tour members purchase rugs. Ali sits in the courtyard and plays the baglama. I got a kick out of the his/hers signs for the water closets:

Tables are set with white linens on the lawn.

We sat at those tables under the trees and had yet another great meal. The food was all locally produced and fresh as could be. We enjoyed our wine and watched the view and roosters and a Turkish squirrel.

Meal:

View:

Turkish squirrel:

Rooster:

After four hours at this unexpected gem of a stop, we got back on the bus for the drive to our gulets.

Navigation:

first Turkey post

next Turkey post

Comments

No comments yet

Add Comment